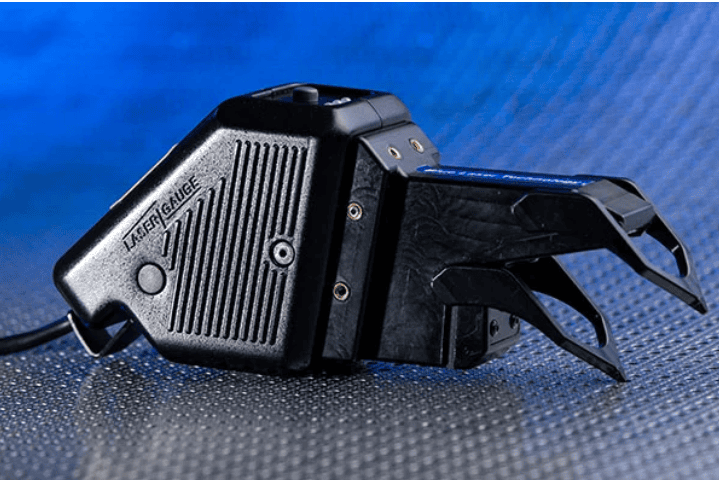

The LaserGauge TS800 USB Sensor is a 2-D scanner that takes stable, precise measurements of the smallest features such as pitting, corrosion, scratches and dents. It is specifically designed for multipurpose or specialized applications that require inspecting and measuring small features on translucent, shiny, or opaque surfaces. The sensor’s small size, light weight, reduced footprint and narrow tapered stem gives it access to highly restricted areas. The TS800 USB sensor is a high-resolution scanner that captures the 2D surface profile and transfers it to a Windows™ PC via a USB 2.0 port for processing and display.

Applications ⬇

Software ⬇

Brochure⬇

➡ TS800 Brochure

Features and Applications

TS800 Single Stripe USB Laser Sensor Features

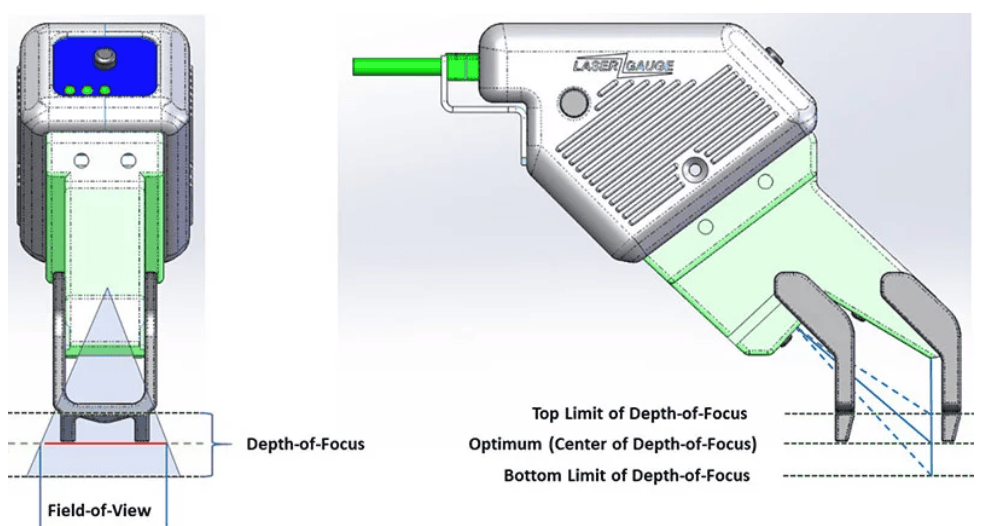

Field of View Options:

- 0.5” (13mm)

- 1.0” (25mm)

- 2.0” (51mm)

Features include:

- Blue single-stripe laser

- Small size, light weight, reduced footprint and narrow tapered stem gives it access to highly restricted areas.

- 1270 scan points over sensor field-of-view

- Measurements in < 1 second

- Resolution up to 0.0004” (10µm)

- Connects to PC with USB cable

TS 800 USB Sensor

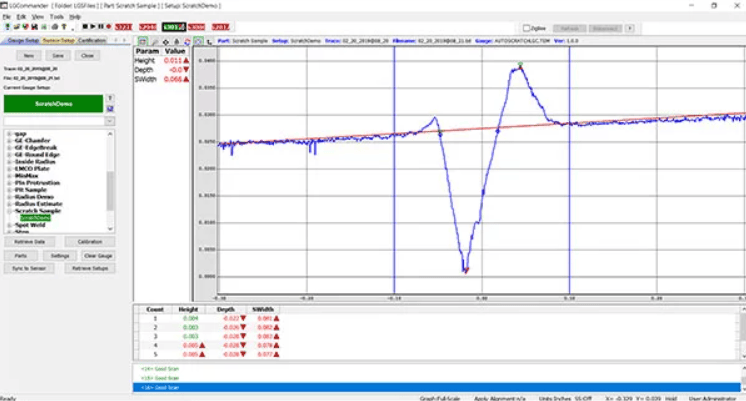

Example of LGCommander display identifying a scratch

Field of View Options:

| FOV Option | Field of View | Resolution | Depth of Focus | Depth Accuracy |

|---|---|---|---|---|

| -F08 | 0.5” (13mm) | 0.0004” (10µm) | ±0.13” (±3mm) | +/-0.00025 (6µm) |

| -F16 | 1.0” (25mm) | 0.0008” (20µm) | ±0.25” (±6mm) | +/-0.0004 (10µm) |

| -F32 | 2.0” (51mm) | 0.0016” (41µm) | ±0.50” (±13mm) | +/-0.001 (25µm) |

Scanning Technology:

TS800 Sensor models are available with Single Stripe Scanning technology and blue lasers.

Blue Laser Technology:

Blue laser technology works accurately on all kinds of surfaces including painted, unpainted, translucent, transparent, some plastic, composite, and shiny.

Configuration Software for LG Controller or PC

Configuration Software for LG Controller or PC

A powerful, Windows™ based software program, LGCommander, is used to configure the sensor and run the algorithm. Scans are displayed in real time and can be saved automatically. Setups, user rights and operational preferences can be safeguarded under passwords, and certification of the gauge for a specific application can be managed through the software.

LGCommander Screen on Laptop

Measurement output includes numerical and graphical displays as well as auditory feedback

Measurement output includes numerical and graphical displays as well as auditory feedback

Display Output

Numerical and graphical results are displayed and can indicate in- or out-of-spec conditions. Operation feedback is provided to assist the operator in obtain the best measurements.

Auditory Output

A variable volume speaker will sound different tones to indicate in- or out-of-spec measurements and errors or misreads.

Data Output

All processed scans and the extracted measurements are automatically saved to the sensor memory for later retrieval. When the sensor is plugged into a PC it will map the data memory as a drive, much like a USB memory stick so that retrieving files is fast and easy.