Automated defect detection to ensure high quality products

Automated defect detection to ensure high quality products

Machine vision and Artificial Intelligence (AI) are increasingly essential in enhancing product quality and consistency in manufacturing. Advanced object recognition systems can identify minute defects that human inspectors might miss, automating labor-intensive tasks and improving overall quality.

Traditional rule-based vision systems find it difficult to detect anomalies and they are modelled to identify a certain defect and would not work in changing environment. However, modern AI-driven vision systems using machine learning (ML) and deep learning (DL) offer more robust inspection solutions, compared to traditional machine vision systems.

Benefits of AI Based Visual Inspections

Enhanced Accuracy

AI visual inspection systems leverage advanced algorithms to detect defects and anomalies with a high degree of precision, reducing the likelihood of human error and ensuring superior quality control.

Improved Efficiency

By automating the inspection process, AI can perform tasks at a much faster rate than manual inspection, leading to quicker turnaround times and increased overall productivity on the production line.

Cost Savings

Implementing AI visual inspection can significantly lower operational costs by minimizing waste, reducing rework, and decreasing the need for extensive manual labor, ultimately improving the bottom line for manufacturers.

Industry Use Cases

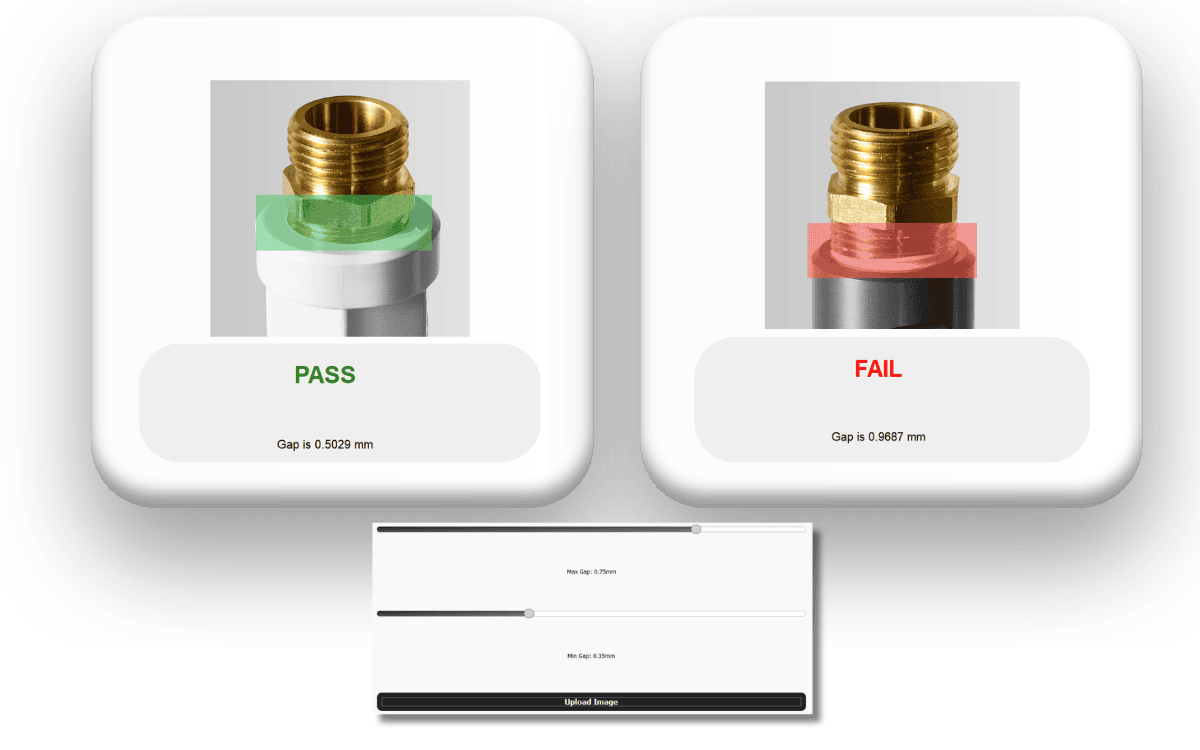

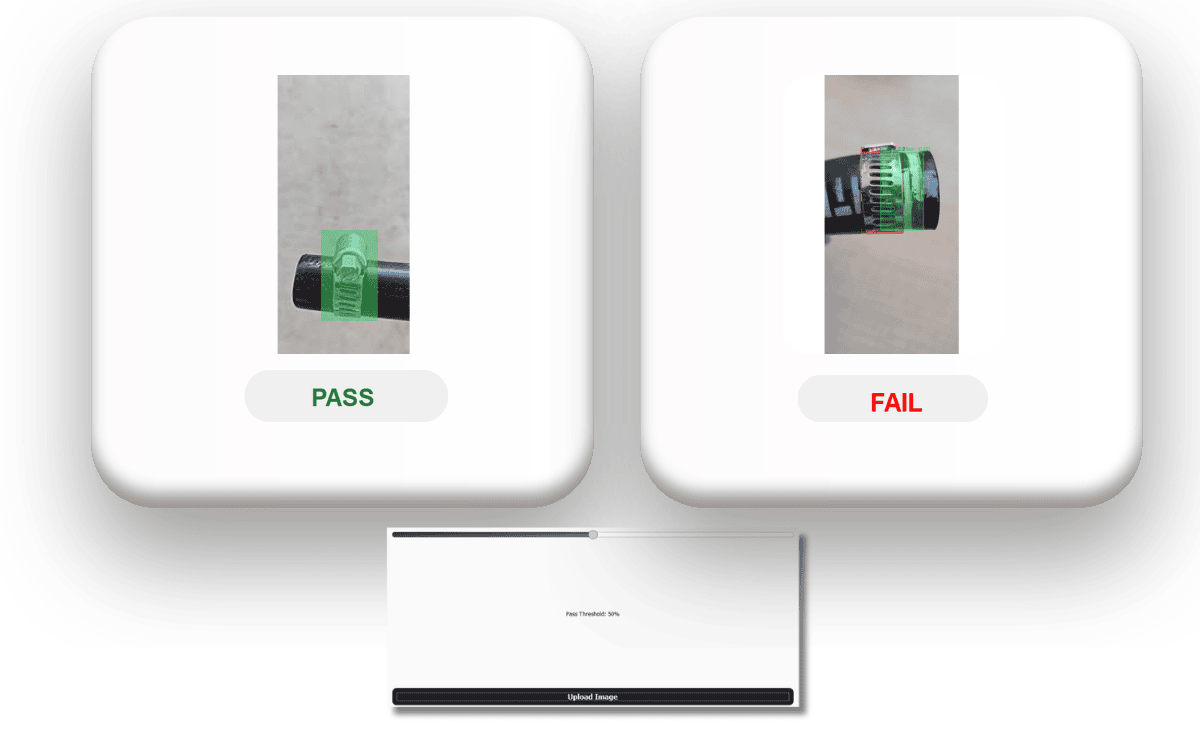

dzInspect Vision: Gap Detection

Identify gaps and verify whether components fall within specified ranges. Our gap detection model can be trained based on industry specific use cases and can help you identify defective part with a click of a button. Gap detection is critical in areas like:

- Assembly Gaps

- Weld Joints

- Circuit board assemblies

- Seals and enclosures

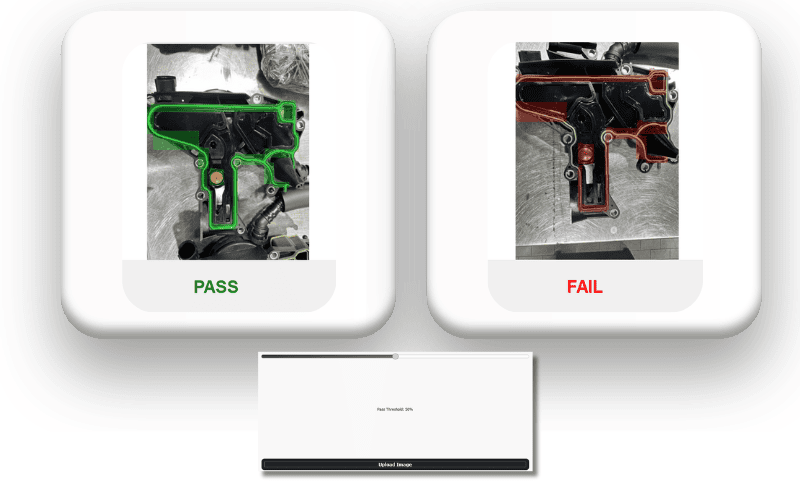

dzInspect Vision: Leak Detection

- Leaks in Pipes and Tanks

- Oil leaks in Engines

- Leaks around Sealant

- Leaks in Hydraulic systems

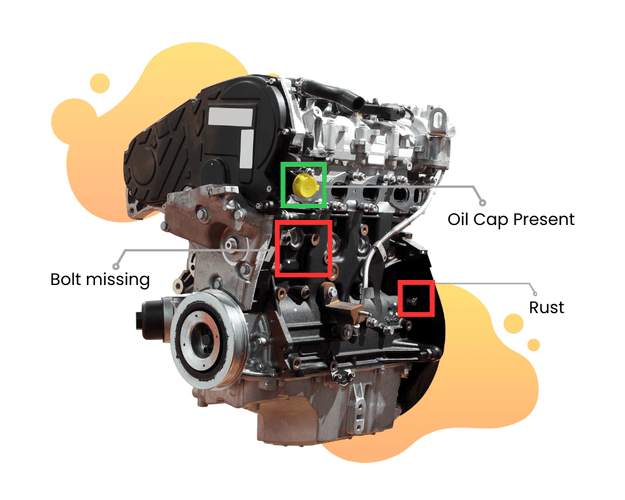

dzInspect Vision: Install View

Ensure the correct installation of parts with our AI-enabled Install View model. Verify that nuts, bolts, caps, barcodes, and other critical components are positioned accurately and meet the specified thresholds. Install View is critical in areas like:

- Engine Hood inspection, Under-body inspection etc.

- Packaging: Barcodes and Labels

- Clamp Check in Ducts and Hoses

Automate your Visual Inspections with AI

AI Advantage

- No human bias involved in inspection

- Inspect complex parts and assemblies

- Detect common defects like dents, cracks, rust and other anomalies not defined in checklist

Adaptable

- Train the AI model according to your use case

- Can adapt with low quality images and changing environment

- Support images from sources like X-ray and Thermal

Deploy and Scale

- Can be easily deployed on Mobile / Tablet/ PC

- Can be deployed ‘In-premises’, or on Cloud (AWS) based on requirement

- Easy to scale to multiple stations / lines

Real-time Data

- Detect defects in real-time with high accuracy

- Real time reporting of results with alerts to mitigate issues in future

- Improved uptime and product quality

Get started with your use case