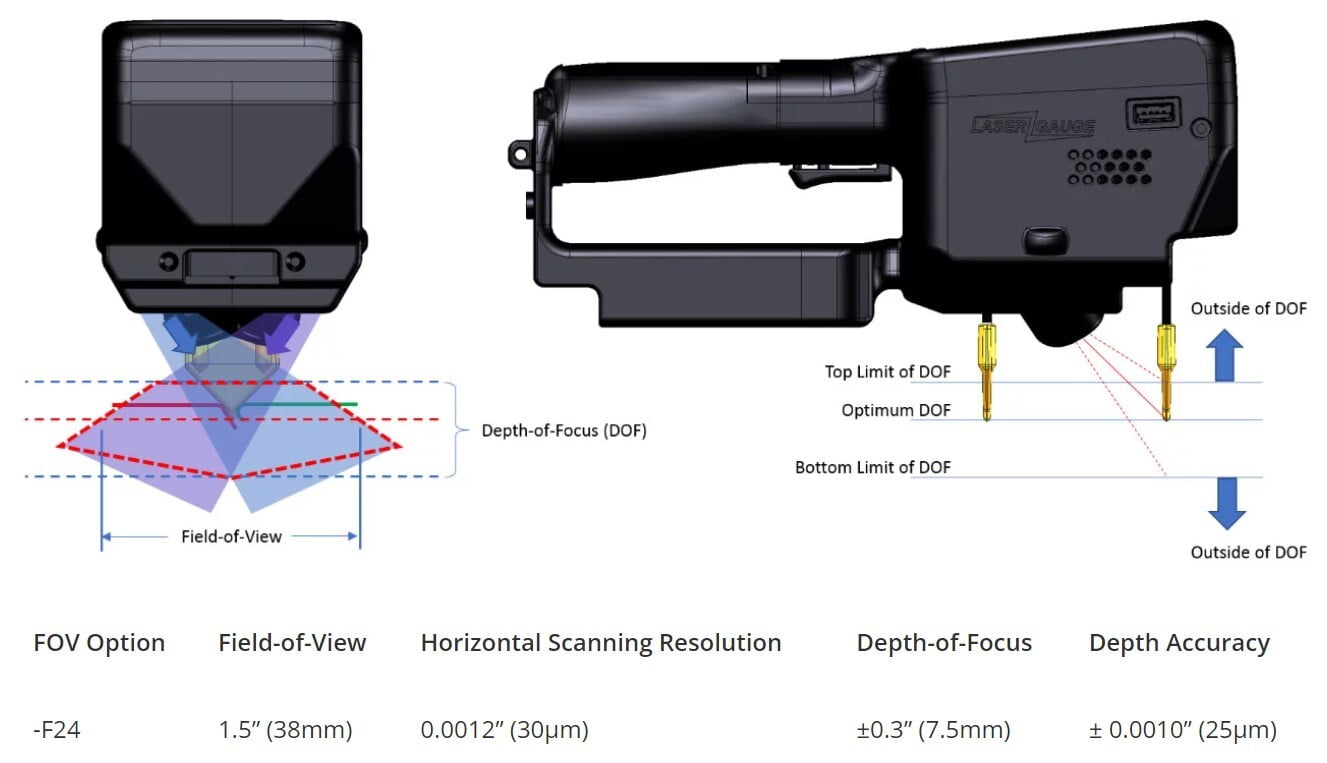

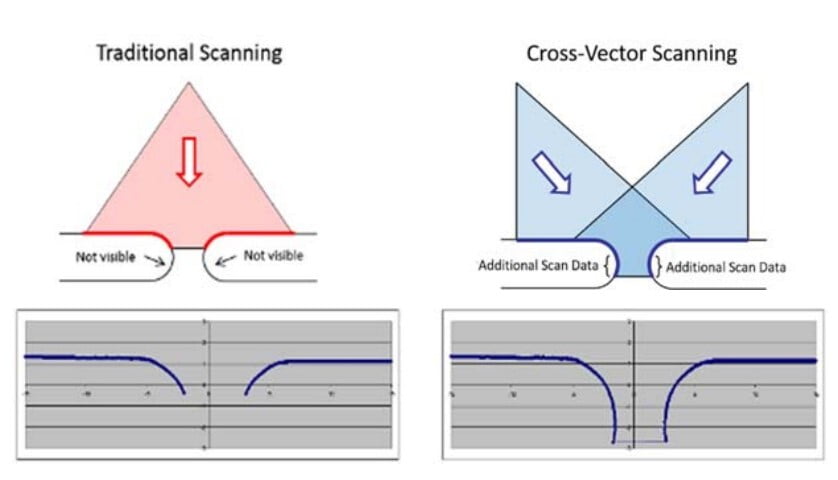

Traditional laser profilers rely on a single laser stripe and imager, which hinders their ability to capture surface points near the radius edge of a gap. In contrast, Cross-Vector Sensors utilize lasers angled towards the inner edges of the gap, intersecting at the midpoint. This configuration enables comprehensive surface scanning, extending from the edges of the radius to the vertical tangent and beyond. As a result, Cross-Vector Sensors deliver more accurate surface profiles and precise measurements of the gap.

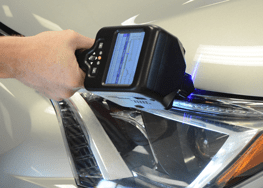

HS763 Cross-Vector Laser Sensors are used exclusively for capturing gap/flush measurements as they can see around edges to accurately create a complete surface profile.

Features

- 1500 scan points over sensor field-of-view.

- 1 GHz DSP processor – measurements are completed in as little as ½ second in the HS763.

- Totally self-contained – no need for external PC or cables for operation.

- Automatic gain optimization – scanning on wide variety of colors/finishes.

- External USB port for interfacing to a USB sensor such as the TS800. The DSP sensor becomes a controller for the sensor.

The HS763 Features 2 Blue Cross-Vector lasers that provide the most accurate measurement of Gap/Flush applications on automotive body panels .

- Takes 0.5-0.75 seconds to obtain a measurement.

- Less sensitive to sensor movement during scanning.

- Measures chrome, opaque materials and transparent material.

Advantages

Advantages

- No movement of sensor required for complete scan.

- No cables to external PC or other hardware required for use.

- Very fast.

- Scanning of headlamps, tail lamps, windows and chrome.

- Proven LaserGauge® technology.