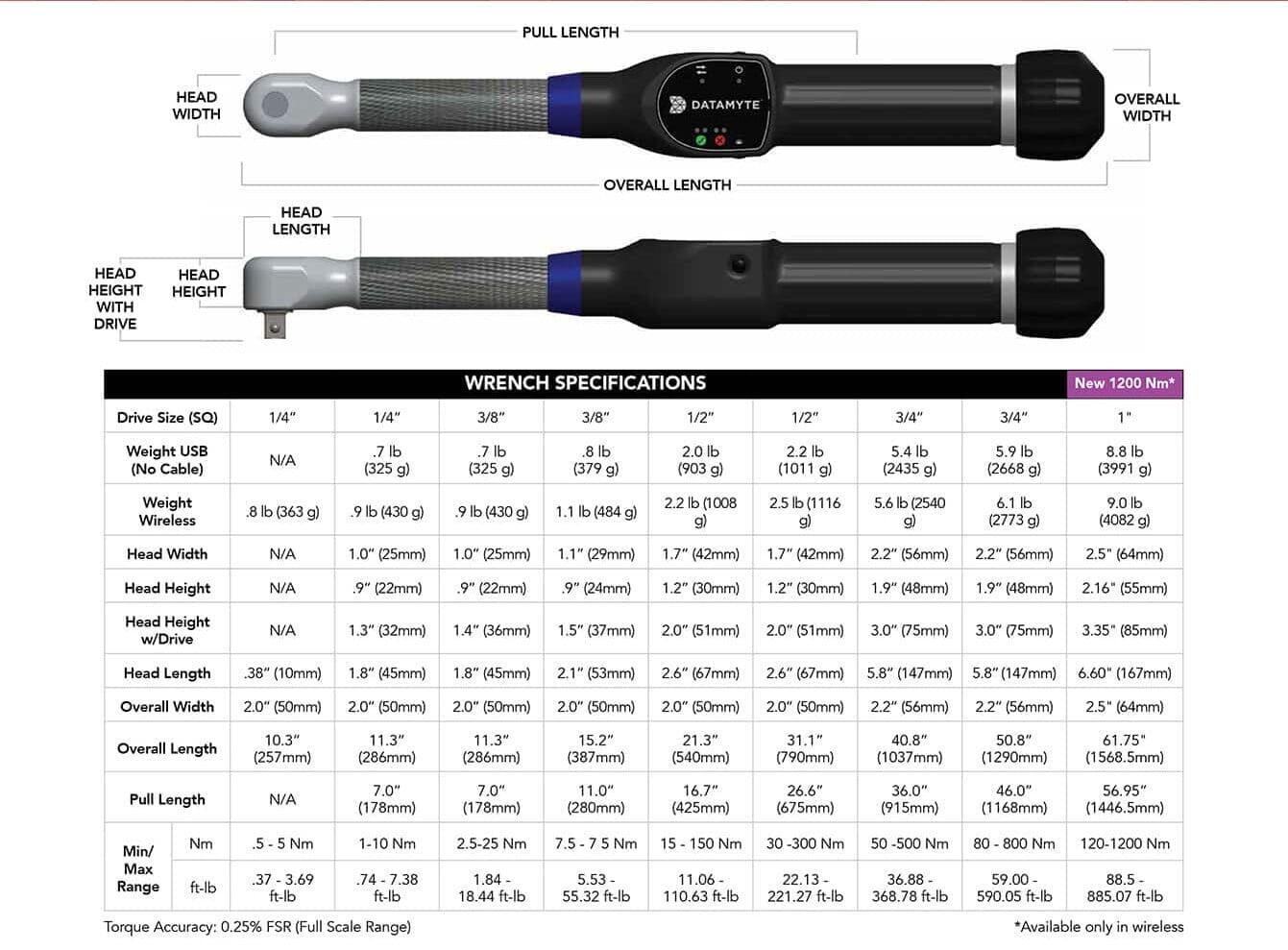

DataMyte Electronic Torque Wrench

DataMyte Electronic Torque Wrench

The DataMyte Electronic Torque Wrench is an electronic torque wrench that is specifically designed for verifying the quality of closure in critical joints, particularly those that are safety-related. The Wrench comes with advanced features such as vibration and LEDs with varying colors that enable the operator to easily determine the outcome of the tightening process. The vibration and LEDs are used to indicate whether the joint has been correctly tightened or not, allowing the operator to quickly identify any issues and take corrective action. This makes the DataMyte Electronic Torque Wrench a highly reliable and efficient tool for ensuring the integrity of critical joints in various applications.

Unleash the power of the Electronic Torque Wrench in any production settings

Expertly crafted with ultra-strong and flexible carboplastic material, making it highly durable and versatile.

Experience precision like never before with Smartwrench technology

Equipped with 6 advanced algorithms that ensure each joint is closed accurately during accuracy audits.

Revolutionize your manufacturing process with our patented residual torque technology

Eliminating any false readings by accurately detecting joints that have been closed at a lower torque, prior to completion.

When quality matters you turn to the industry precision wrench expert that aligns the latest technology with your quality goals to drive profitability to your bottom line. When it’s your job to ensure that safety-critical joints are correct, trust only the best to the task – LightStar™ Torque Wrench series.

Removes False Highs & Lows

Low Readings due to wrench release before fastener rotation.

High Readings due to overshoot or high distinction.

7 Steps of Residual Torque Audit

7 Steps of Residual Torque Audit

DATAMYTE consults with some of the top automotive and aerospace companies to build residual torque programs that increase productivity, lower costs and provide invaluable insights into the performance on the lines.

Electronic Torque Wrench Algorithms

Electronic Torque Wrench Algorithms