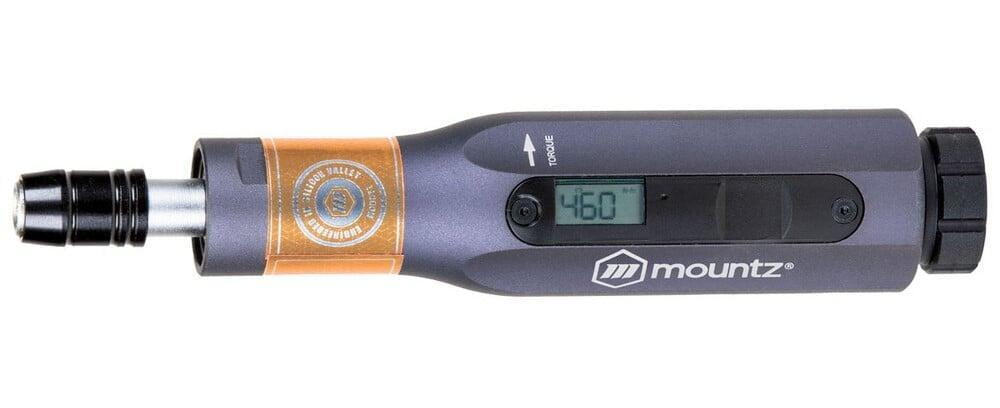

FGA Adjustable Torque Screwdrivers

The Mountz FGA adjustable cam-over torque screwdriver is an error-proofing tool that allows engineers to reduce the risk of over-torque on their assembly lines in production environments with critical fasteners often found in electronics, aerospace, and automotive manufacturing. Torque range suitable for micro, low, and medium torque applications.

Using a clutch mechanism, cam-over tools prevent the operator from applying too much torque to the fastener - preventing over-torque events, broken components, costly product returns, and safety risks.

Cam-over technology reduces the possibility of operator error in both fastening directions, which ensures correct torque is applied and prevents fastener breakage. Providing the operator with an adjustable tool provides flexibility where torque values may need to be adjusted on demand, like maintenance, field service, and research applications.

All FGA hand tools have a calibration life of 4x ISO standards that is unmatched by any adjustable torque screwdriver provider.

Redefining Fastening Reliability.

Know more About

FGA Adjustable Torque Screwdrivers

With FGA, you can Proceed with Confidence

- Low-impact poka-yoke torque screwdriver prevents over-torque and vibration on sensitive components and delivers repeatability, traceability, and precision for all tightening applications.

- Quick torque setting with a digital torque scale provides an accurate and straight forward adjustment process— the scale easily converts between metric and standard units.

- Cam-over technology ensures correct torque is applied and reduces fastener breakage.

- Our tools are durable & reliable. We provide an Industry leading warranty: 2 years unconditional. Lifetime against defects. Calibration life exceeds ISO standards.

| Model: | FGA-8 | FGA-20 | FGA-40 | FGA-80 |

| Item #: | 076720 | 076721 | 076722 | 076723 |

| Drive Size: | 1/4" F/Hex | 1/4" F/Hex | 1/4" F/Hex | 1/4" F/Hex |

| American: | 1.6 - 8 lbf.in | 2 - 20 lbf.in | 4 - 40 lbf.in | 8 - 80 lbf.in |

| S.I.: | 18 - 90 cN.m | 22 - 226 cN.m | 0.45 - 4.5 N.m | 0.9 - 9 N.m |

| Metric: | 1.8 - 9.2 kgf.cm | 2.3 - 23 kgf.cm | 4.6 - 46 kgf.cm | 9.2 - 92 kgf.cm |

| Tool Weight: | 13 oz. | 13.1 oz. | 22.4 oz. | 13.3 oz. |

| Tool Length: | 7.2 | 7 | 12.5 | 7 |